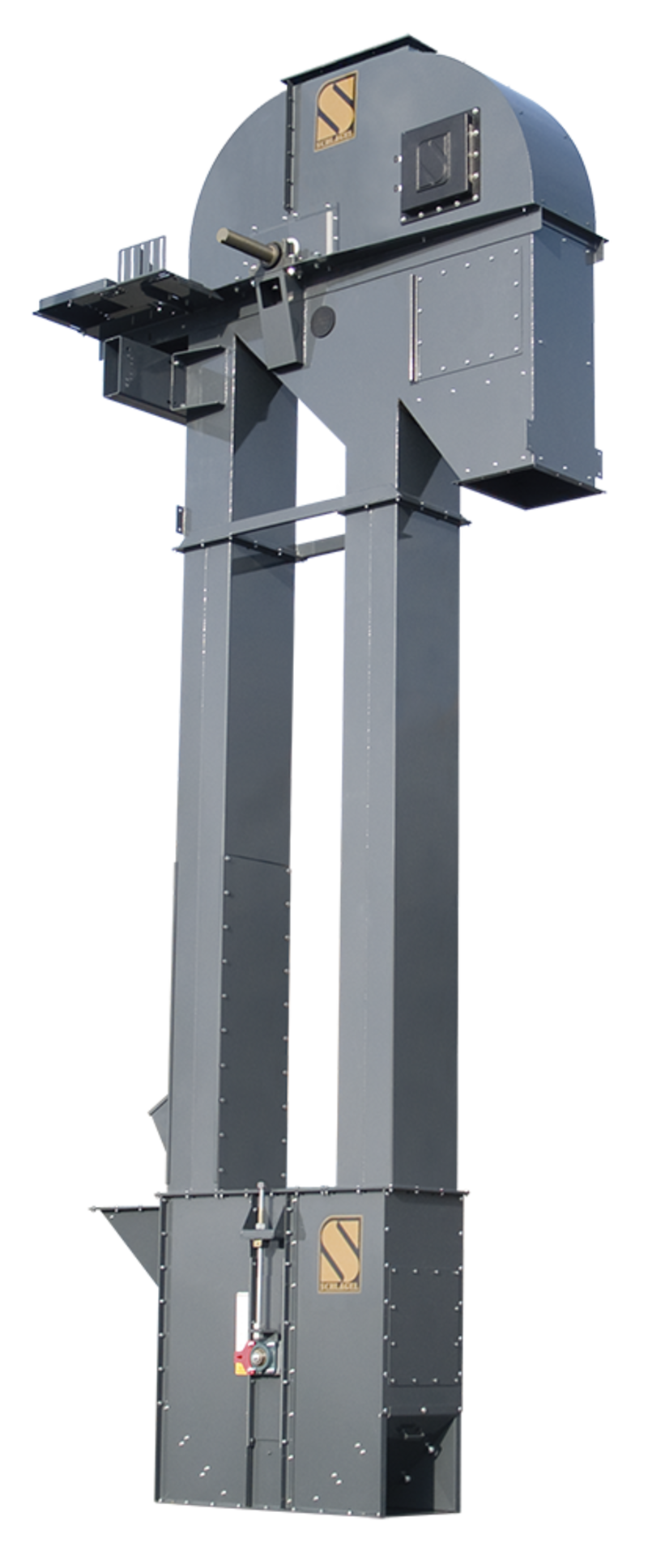

Bucket Elevators

Schlagel belt and bucket elevator legs compliment our line of handling equipment with performance and quality proven in the industry since 1957. As with all our equipment, we guarantee the performance and quality of these legs and design them for high reliability and low maintenance.

We manufacture standard models in sizes and capacities demonstrated by our years of experience to best fit the needs of most applications. We calculate capacities at water level plus 10% cup fill and use low belt speeds in both single and multiple row cup models.

Larger sizes and models with special features are always available on request to fit your needs. Our engineering department is ready to help you design the right equipment to meet the special needs of your application.

The head section is designed and ruggedly constructed to withstand the torque of drive components, maintain alignment and to aid in maintenance. We fabricate the lower portion from 10 GA steel and the hood from 12 GA steel with a pressure relief door on the top of the leg as a standard feature. We provide standard A.R. steel liners and offer additional optional liners to extend service life (see options page). The head pulley is crowned, lagged and mounted on the head shaft with tapered bushings to eliminate side movement. We select bearings to handle severe service with roller bearings standard on larger sizes and provide jack-bolts under the head shaft bearings on all models to allow ease in field shimming for proper belt tracking.

The standard head section comes with one grated hinged door in the hood section, which can be place on either side of the head for inspection; most sizes have a pressure relief vent located on top of the hood. There are two rubber plugs that are used to inspect the pulley lagging. Always follow proper lock out tag out procedures before removing any doors or plugs.

Heavy 7 or 10 GA bolted steel construction boot provides a solid base with heavier gauges available (model and application determines material gauge). We include many standard features to insure continued ease in operation and maintenance. Proper belt tension is easily maintained with plated take-up screws and solid brass take-up nuts. Standard crowned boot pulleys are available in either drum or wing style. Cut-outs are located on both up and down sides with a boot pocket installed on the up side and bolted cover plate on the downs sides as standard. Clean-out doors on both ends of the boots are also standard features.

Gravity take-up and self-cleaning boots can be supplied at additional cost (see options page 58). We will also drill and tap boot shafts for speed monitors on request.

Most materials should be fed into the up side. Light and bulky materials give better cup fill when fed on the down side. Our up side inlet location insures that material enters the cups at or above the pulley centerline.

Standard Boot:

Optional Boot:

Our trunking provides superb dust tight and weather tight protection with continuous jig welded 12 or 10 GA steel construction with heavier gauges available (material gauge depends on model and application). Trunking is standard in 10 foot lengths with alignment ties provided for each joint. All trunking seams are butt welded and end flanges are heavy flat bar so no overlapping metal parts will trap corrosive moisture or product.

The heavy gauge inspection section allows full access to the front and back of belt and cups. The operator may also view cup fill through the standard inspection door.

Rubber belt with vented plastic cups is standard on Schlagel legs. Special belting such as PVC, high temperature or food grade belt is available on request as are steel cast, or nylon cups in non-vented or other venting patterns. Material type, feeding arrangement, head pulley diameter and belt speed, along with many other more subtle factors, affect the loading and discharge characteristics of bucket elevator cups and the performance of your leg.

Contact the factory for special requirements. Chain legs are also available on request.

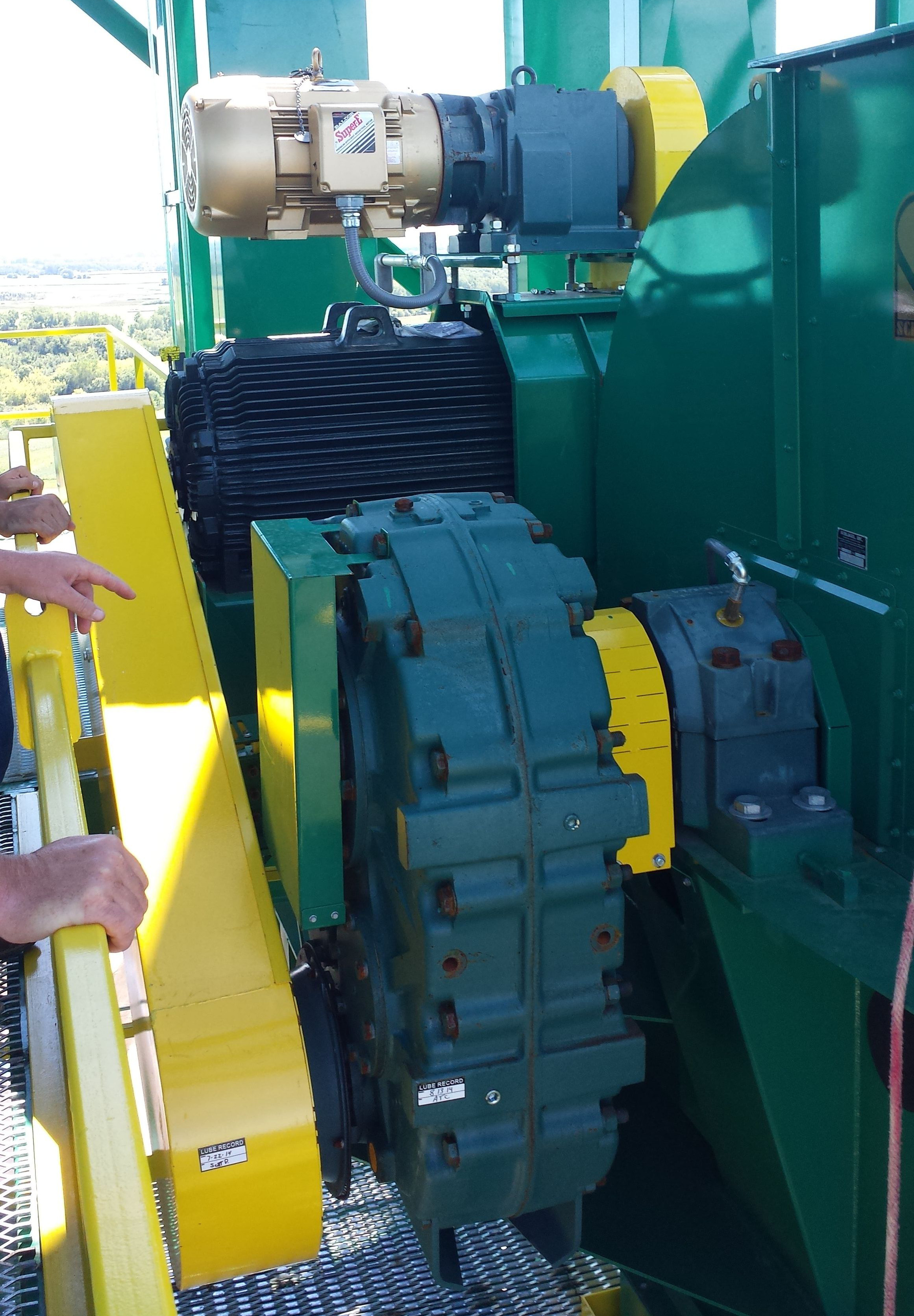

Standard drives are shaft mounted gear reducers with backstop. Dual drives are available for very high horse power requirements. When furnished with our legs, drives are complete with sheaves, belts and belt guards. We can also supply motors. Unless otherwise specified, drives are supplied for right hand mounting and Class II service.

Other classes and types of drives can be quoted per request.

Optional Creep Drive Shown Below

| Name | Type | Size |

|---|---|---|

| Installation & Operator | manual | 0 bytes |

| Platform Assembly | manual | 0 bytes |